McGill researchers demonstrate potential for on-the-spot 3D-printed tests

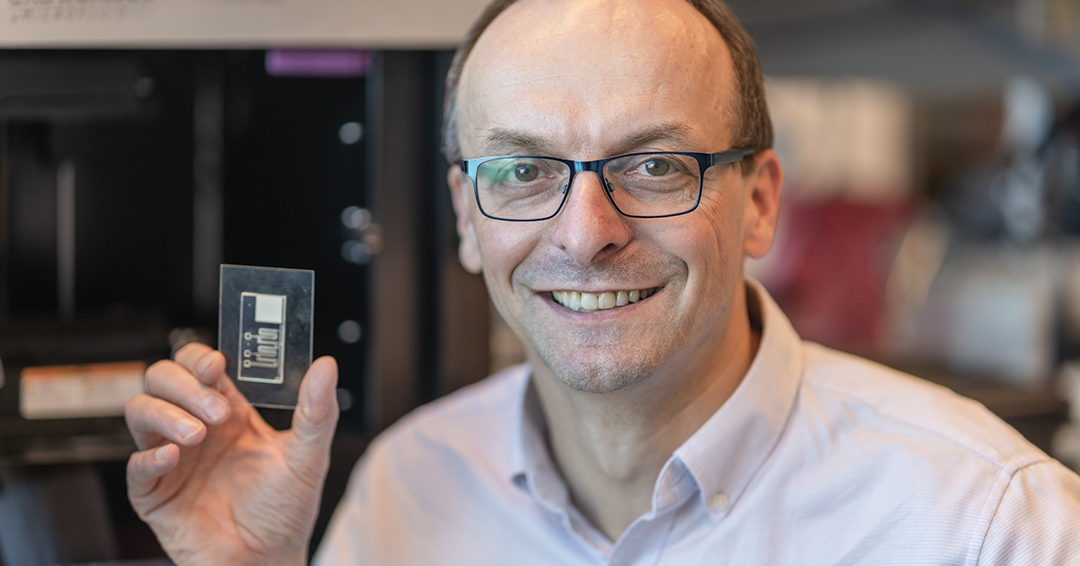

As part of a recent study, the results of which were published in the journal Advanced Materials, researchers from McGill University were able to manufacture a lab-on-a-chip from a digital file using a 3D printer in just 30 minutes.

The McGill team invented a microfluidic chip, or lab-on-a-chip, technology that they’ve named a “capillaric chip.” Capillaric chips are microfluidic chips that function as fluidic microprocessors powered by capillary phenomena – the very phenomena by which a spilled liquid on the kitchen table spontaneously wicks into the paper towel used to wipe it up.

These chips differ from computer microprocessors in many fundamental ways: the liquid-handling operations are structurally encoded in the microarchitecture of the fluidic circuit; they are single-use because the decoding occurs as liquids fill and drain different sections of the circuit according to the structurally encoded program; and they are self-powered by capillary flow, not necessitating any peripheral connection or a battery for power – a simple paper strip suffices.

“We were able to develop a ‘microfluidic chain reaction’ to employ with the chip that could encode chains of hundreds of liquid-handling events and execute them one after the other, akin to a computer code being executed line-by-line,” notes Ahmad Sohrabi-Kashani, PhD, one of the study’s first authors who was conducting postdoctoral work with David Juncker, PhD, at McGill during the study.

Leveraging an opportunity in the COVID-19 era

The COVID-19 pandemic ushered in an era of widespread home testing using rapid antigen tests. Accessible in many jurisdictions for self-testing at home, these tests employed capillary flow to drive a drop of the sample supplied to the inlet across a thin membrane into a hidden capillary pump – basically a blotting paper – for about 15 minutes.

However, these tests had to be obtained from a pharmacy or ordered online and were only made available in the latter stages of the pandemic. Rapid antigen tests have limited fluidic functionality as they can only drive one liquid across the strip. As a result, most diagnostic tests are still operated in central laboratories or using programmable lab-on-a-chip systems that transport minute amounts of samples, reagents and buffers according to pre-defined sequences.

“We used 3D printers to make a variety of capillaric chips including one for evaluating the presence of antibodies against COVID-19,” explains Vahid Karamzadeh, PhD, the study’s other first author who was a PhD student at McGill also under Prof. Juncker’s supervision. “Upon printing of this chip and loading it with reagents, the concentration of antibodies could be quantified and could be used to evaluate if antibodies protective against a disease are still present.” As a final demonstration, the researchers showed that the capillary pump, which also relied on blotting paper, could also be 3D-printed, resulting in the digital manufacturing of a fully functional lab-on-a-chip system.

“Our findings hold significant importance as they transform the manufacturing of functional ready-to-use microfluidic systems in the form of capillaric chips,” says Prof. Juncker, Chair of the Department of Biomedical Engineering at McGill and senior author on the study. “Traditional diagnostics require peripherals, while ours can circumvent them. Our diagnostics are a bit what the cell phone was to traditional desktop computers that required a separate monitor, keyboard and power supply to operate. Moreover, in our case one could now also 3D print the ’cell phone’ at home thanks to the new affordable 3D printing inks, designs for fluidic valves and integrated pumps we introduced. This could thus impact the manufacturing of microfluidic chips and diagnostic tests which currently is confined to specialized, expensive facilities; we propose to replace these facilities using readily available digital light processing (DLP) 3D printers and digitally manufacture capillaric chips at a cost of a few tens of cents each from downloadable designs.”

The future of accessible testing

Will you be able to 3D print your diagnostic at home? While this work demonstrates the possibility of a chip pre-programmed to execute complex fluidic functions, important gaps remain, including the need to supply the reagents needed to run an assay. The regulatory approval needed for this type of medical device, for which a framework currently does not exist, is another obstacle.

The researchers are hopeful that their findings will spur the discussions needed to be able to realize the potential they believe exists. “This advancement has the capacity to empower individuals, researchers, and industries to explore new possibilities and applications in a more cost-effective and user-friendly manner,” notes Prof. Juncker. “This innovation also holds the potential to eventually empower health professionals with the ability to rapidly create tailored solutions for specific needs right at the point-of-care. Not only does this achievement signify a milestone in the realm of decentralized manufacturing of diagnostic and analytical tools, but thanks to the new generations of ever more powerful and affordable 3D printers, it also sets the stage for the advent of home-based manufacturing of functional capillaric chips and diagnostic devices. Indeed, we have reformulated the ink to make it compatible with liquid crystal display (LCD) 3D printers that cost less than $300, and are currently using them to print functional capillaric chips. The affordability and user-friendly nature of this technology could make point-of-care testing more accessible in both resource-rich and resource-limited settings, and lead to faster diagnosis and ultimately improved patient outcomes led to faster.”

Related:

Vahid Karamzadeh*, Ahmad Sohrabi-Kashani*, Molly Shen and David Juncker. Digital Manufacturing of Functional Ready-to-Use Microfluidic Systems. Advanced Materials. (* Equal Contribution.) DOI: https://doi.org/10.1002/adma.202303867

Yafia, M., Ymbern, O., Olanrewaju, A.O., Parandakh, A., Sohrabi Kashani, A., Renault, J., Jin, Z., Kim, G., Ng, A. and Juncker, D., 2022. Microfluidic chain reaction of structurally programmed capillary flow events. Nature, 605(7910), pp.464-469. DOI: https://doi.org/10.1038/s41586-022-04683-4

3D printed ‘machines’ powered by microfluidic chain reactions