By Dr. Julian Willett, PhD student in Qualitative Life Sciences

A cough in the Emergency Room. A cough in the supermarket. A cough from your child. In the face of this generation’s unprecedented challenge brought about by the current global pandemic, anxiety comes from all angles. Even with restrictions gradually being lifted, the months spent fearing an unseen, indiscriminant, deadly entity remain etched in the walls of consciousness. I am no stranger to these feelings given the love I have for my wife and my family. I completed my medical coursework in New England in August and was rotating in the hospital up to March to return in July with work at home in between given the need to limit provider exposure. While home, I decided that I wanted to do something about the pandemic aside from serving on my hospital’s Personal Protective Equipment (PPE) innovation committee. Given my hobbies of DIY and 3D-printing, I brought these pastimes together to serve fellow healthcare providers during this four-month period.

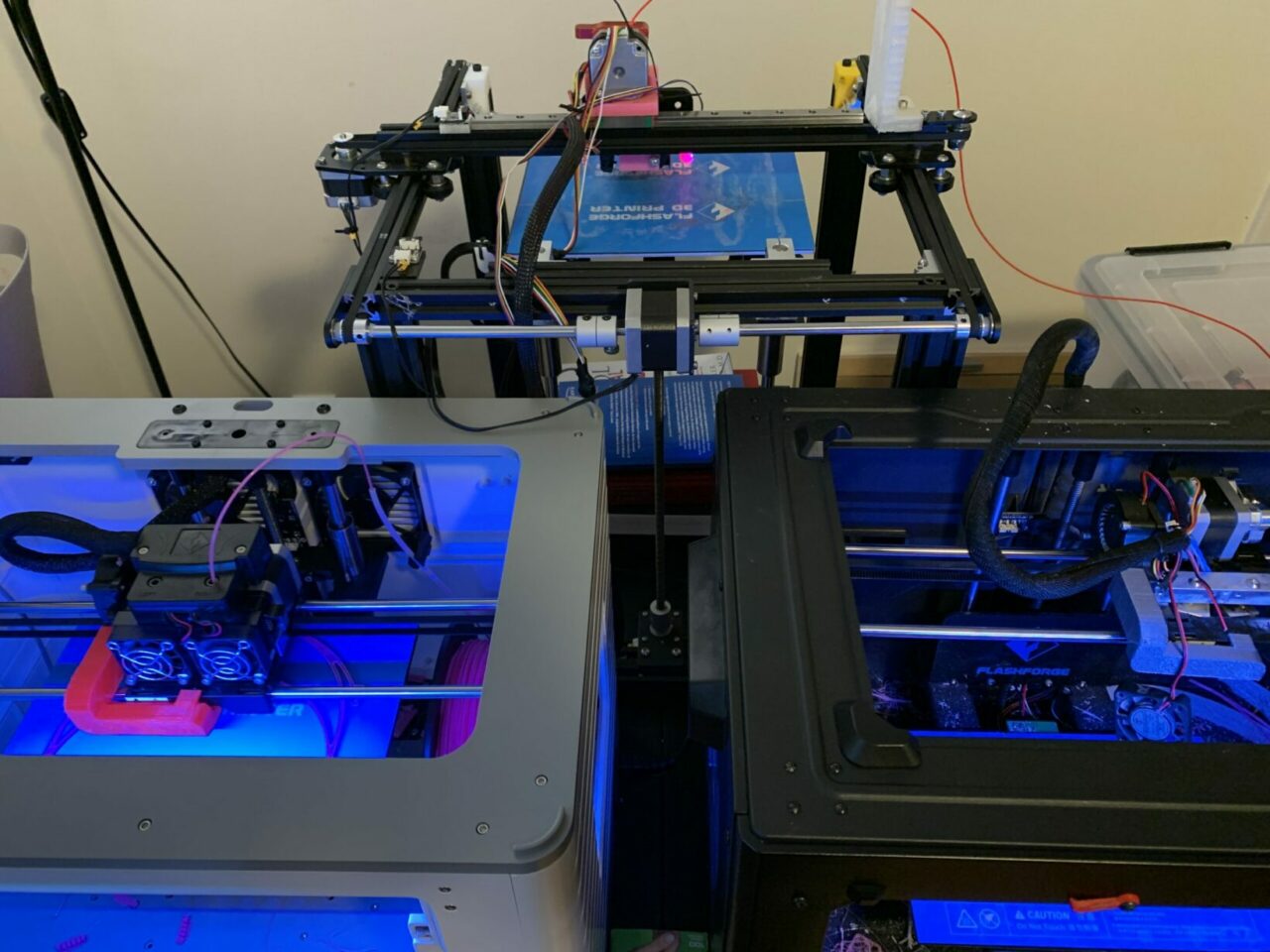

3D printing is a manufacturing technique where plastics are passed through a heating chamber on a moving axis to deposit material on a plate to create a three-dimensional object one had designed. Think of adding icing to a cake, except a computer controls it. COVID-19 expanded the applications of 3D-printing to PPE given the need for face shields and medical equipment that was in short supply. 3D-printing is an advantageous manufacturing process given that items can to an extent be disinfected and sourced locally by “maker groups” or manufacturers.

I volunteered for a group called “Operation Dynamo” and 3D-printed items that were required to make face shields on behalf of hospitals and “maker groups” who deliver the face shields to hospitals who express the need. Given that respiratory droplets with virus can transmit disease if they go into another’s eyes (and nose and mouth), face shields addressed the eye protection deficiency present with a surgical mask. I printed a visor or a reinforcing piece for a face shield and mailed it to a requesting party that has included the University of Texas Southwestern, maker groups in South Carolina and New York, and Maker Nexus in California. The parties received the units and completed the design using laser-cut transparent material, that can be a plastic called PETG (similar to plastic used in Tupperware) or acrylic (plexiglass). Then the group either uses it or gives it to those who are in need. Over the course of those four months, I printed 360 shield reinforcers, which hold the transparent material in the desired geometry and 200 face-shield visors, the piece over the forehead with notches to join with the transparent sheet, equating to 560 face shields. Visors needing reinforcers were created with injection molding. Each shield translated to protection when serving dozens of patients a day that is common in EDs and medical services.

After nine months, the PPE shortage has greatly improved. As I have found in my work 3D printing, taking care of patients, and spearheading other community service efforts, the greatest impact can be felt when groups come together for a purpose as opposed to individuals acting in isolation. While we are not all healthcare professionals, all of us have something interesting about ourselves, whether it be a hobby, a passion, or a story. In this unprecedented time, we can all take steps towards making the world a better place, easing suffering, and remembering those who have been lost or have directly faced their own mortality, even with physical isolation and social distancing. All it takes is a willingness to serve. With this, we can create the future we wish to see.

Dr. Julian Daniel Sunday Willett completed medical school at Tufts University between 2016-2020 and has started his PhD at McGill University in the department of Quantitative Life Sciences. He is excited for his future career as an academic, research-predominant physician scientist with medical board certification in Anatomic Pathology. His current research topic is genetic variation and evolution of SARS-CoV-2 in Canada over the course of the pandemic. This work is being completed in the lab of Dr. Ioannis Ragoussis in Genome Sciences.